Buffer Tanks

Carbon Steel Buffer Tanks (VTA Series)

We have 3 Versions in our Product Range to start with:

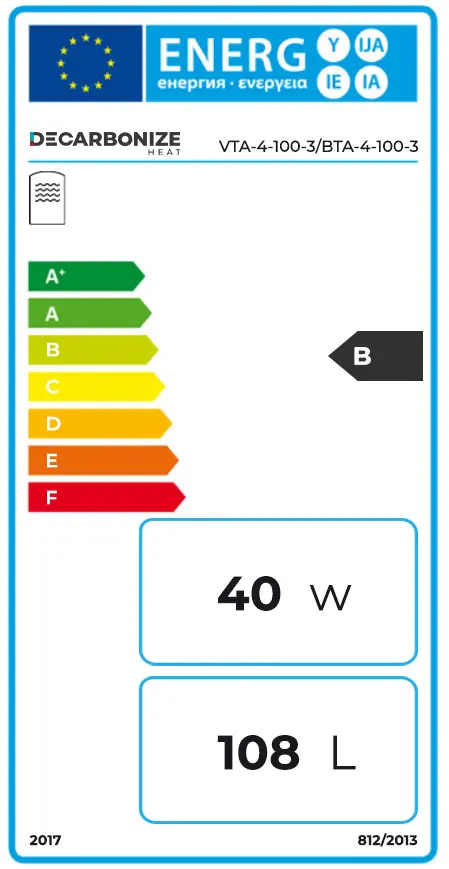

VTA-4-100-3 (100 litres)

VTA-4-150-3 (150 litres)

VTA-4-200-3 (200 litres)

VTA-4-100-3 (100 LITRES)

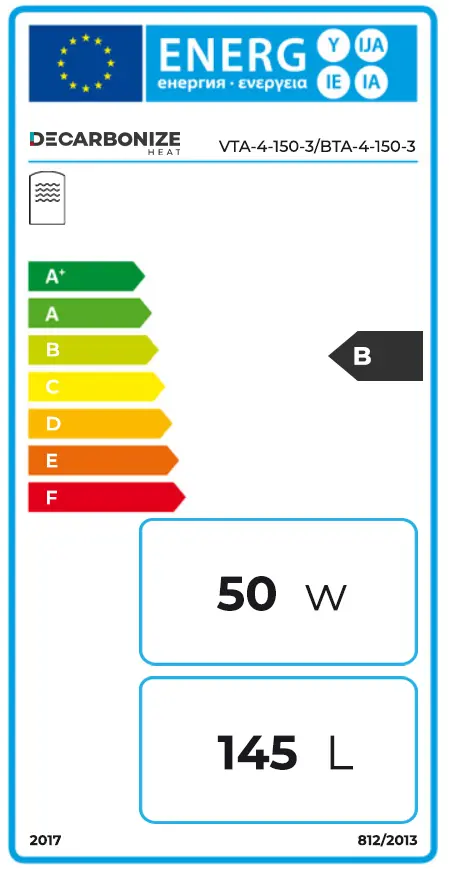

VTA-4-150-3 (150 LITRES)

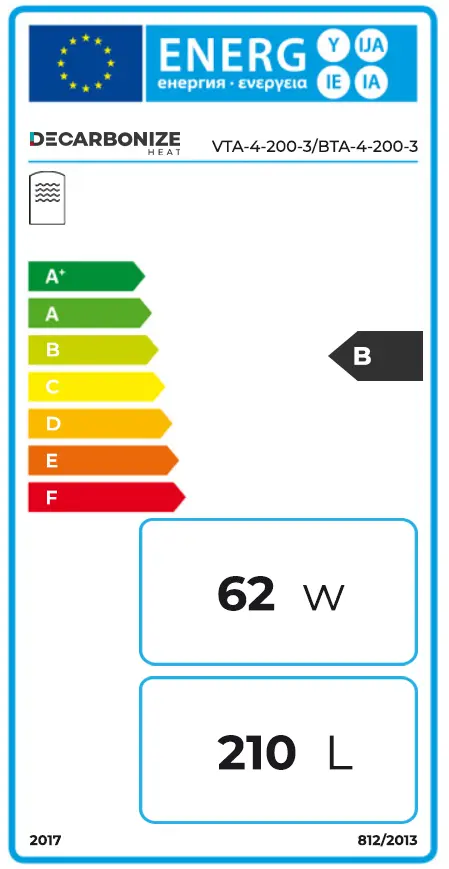

VTA-4-200-3 (200 LITRES)

Technical Data

Tank Material

Carbon Steel with a Thickness of 2-3 mm. It depends on the Volume of the Tank.

Maximum Working Pressure

6 bar

Hard Insulation

PPU 50 mm (for Tanks 80-300 L), 35 mm (for Tanks up to 80 L)

Outer Casing is PVC

Textile Jacket

Product Information "Decarbonize Buffer Tank for Heat Pump"

High-Quality Decarbonize Buffer Storage Tanks for Heat Pumps: Efficient energy supply in Various sizes.

Decarbonize Buffer Tanks are specially designed to Optimise your Heat Pump Systems. An essential component in the application of Buffer Storage Tanks for Heat Pumps, our Tanks help to increase your Energy Efficiency. They are made of Robust Carbon Steel and are available in 100, 150 and 200 Litre capacities.

The Buffer Tanks operate at a maximum Pressure of 10 bar, while the working Pressure at the Heat Exchanger inlet is 3 bar and 6 bar on the Heating Circuit side. An additional outer PVC textile cover provides further protection, while the High-Quality PPU insulation optimally stores Heat and Minimises heat loss.

With the Decarbonize Buffer Tanks you have the possibility to connect several Heat sources and maintain a continuous Heat Supply. In addition, You can use the Hot Water from the Buffer Tank to De-Ice the Heat Pump during the winter months.

Integrating Buffer Tanks into your Heat Pump system offers significant Energy Savings. By Reducing the Frequency with which the Compressor is switched on and off, the lifetime of your Heat Pump system is extended and the overall Energy Consumption is reduced. In addition, Buffer Tanks can balance the flow of Heat Systems and ensure an even and Constant Supply of Heat or Cold.

For optimal use, we recommend Calculating 10-15 Litres of Buffer Storage volume per kilowatt of Heat Pump Capacity. In addition, our Buffer Storage Tanks offer the option of connecting Thermoelectric Heating Elements.

Whether for a Heating or Cooling System, Decarbonize Buffer Tanks are a Sustainable and Energy-Efficient choice. With an EER Class B (on a Scale from A+ to F), they are Proof of our Commitment to Energy Efficiency. Choose Sustainability and Efficiency – choose Decarbonize Buffer Cylinders for your Heat Pump.

Characteristics

Capacity

200-10000 l

Tank Working Pressure

10 bar

Working Pressure at Heat Exchanger Input

3 bar

Working Pressure on the Side of Heating Circuit

3 bar

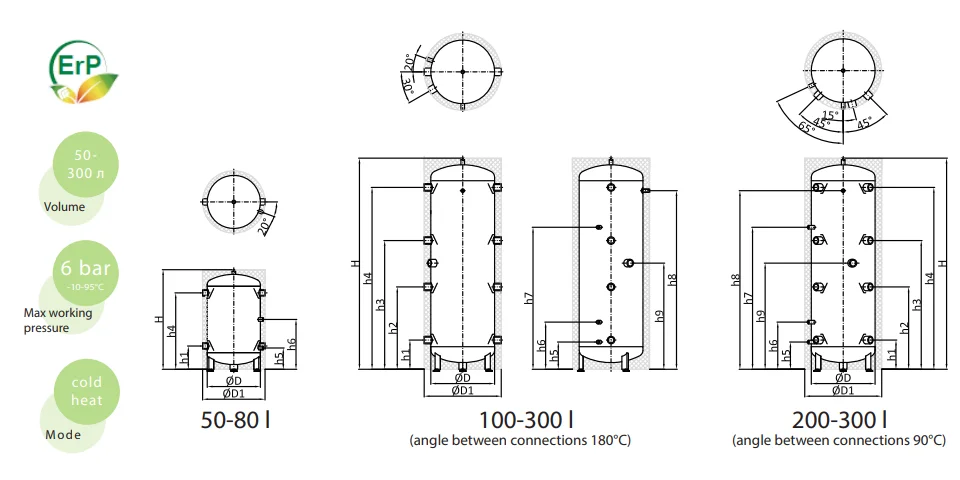

VTA-4

H – Ventilation

h1-h4 – Fitting Pipes for Delivery and Return lines of Heating circuits

h5 – Technological Fitting Pipe

h6-h7 – Fitting Pipes for Temperature Sensor

h8 – Fitting Pipes for Termometer

h9 – Fitting Pipes for EHE

| Vtank, L | Dimensions, mm | Energy Efficiency Class | Fixing Dimensions, mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | ∅D1 | ∅D | h1 | h2 | h3 | h4 | h5 | h6 | h7 | h8 | h9 | ||

| 50 | 500 | 480 | 400 | B | 175 | – | – | 325 | 160 | – | 250 | – | – |

| ½” | 1¼” | ½” | ½” | ||||||||||

| 80 | 750 | 480 | 400 | B | 175 | – | – | 575 | 160 | – | 375 | – | – |

| ½” | 1¼” | ½” | ½” | ||||||||||

| 100 | 980 | 510 | 400 | B | 190 | 390 | 590 | 790 | 175 | 290 | 690 | 765 | 540 |

| ½” | 1¼” | ½” | ½” | 1½” | |||||||||

| 150 | 1280 | 510 | 400 | B | 190 | 490 | 790 | 1090 | 175 | 290 | 890 | 1065 | 640 |

| ½” | 1½” | ½” | ½” | 1½” | |||||||||

| 200 | 1340 | 590 | 480 | B | 220 | 545 | 795 | 1120 | 205 | 355 | 895 | 1095 | 670 |

| ½” | 1½” | ½” | ½” | 1½” | |||||||||

| 250 | 1590 | 590 | 480 | C | 220 | 620 | 970 | 1370 | 205 | 355 | 1070 | 1345 | 800 |

| ½” | 1½” | ½” | ½” | 1½” | |||||||||

| 300 | 1840 | 590 | 480 | C | 220 | 700 | 1140 | 1620 | 205 | 355 | 1240 | 1595 | 970 |

| ½” | 1½” | ½” | ½” | 1½” | |||||||||